Introduction

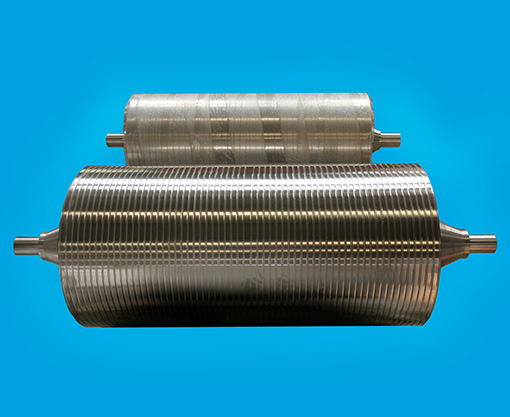

The bottom roll of the wide and thick plate heat treatment furnace is mostly used in the normalizing furnace and quenching furnace. Under the nitrogen and hydrogen protective atmosphere, the temperature is 550 ° C - 950 ° C in the furnace, and the wide and thick plates are transported evenly and quickly to complete the heat treatment process; The diameter is 300-400mm, the roll body is centrifugally cast, and the journal head is statically cast.Common steel grades: ZG40Cr25Ni20Si2, ZG14Ni32Cr20Nb, ZG45Ni48Cr28W5Si2.

1、 Introduction to furnace bottom roll

The bottom roll of heat treatment furnace is mainly used for continuous carburizing and nitriding furnaces. Under the protective atmosphere, the temperature is 550 ° C - 850 ° C in the furnace, and wide workpieces are transported evenly and quickly to complete the heat treatment process; The diameter is 100-200mm, the roll body is centrifugally cast, and the journal head is statically cast.

The sink roll is used in the zinc pot system of the galvanizing line. The continuous galvanizing process is completed through the three rolls and six arms of the zinc pot system. The three rolls in the zinc pot are all passive rolls. The roll body is centrifugally cast. The combined shaft head is statically cast. The common specification is 500-800.

The bottom roll of the wide and thick plate heat treatment furnace is mostly used in the normalizing furnace and quenching furnace. Under the nitrogen and hydrogen protective atmosphere, the temperature is 550 ° C - 950 ° C in the furnace, and the wide and thick plates are transported evenly and quickly to complete the heat treatment process; The diameter is 300-400mm, the roll body is centrifugally cast, and the journal head is statically cast.

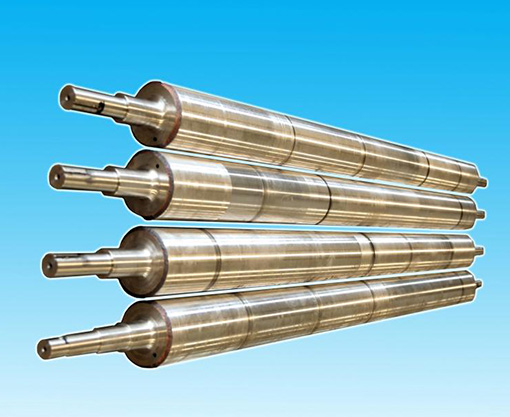

The furnace roll of horizontal annealing furnace is mostly used for horizontal annealing furnace of continuous annealing and galvanizing lines. Under nitrogen hydrogen protection atmosphere, the temperature is 750 ° C - 950 ° C in the furnace, and the strip steel is uniformly and rapidly transported to complete the annealing process; The diameter is 100-500mm, the roll body is centrifugally cast, the transition section is statically cast, and the shaft head is mostly forged.

The vertical annealing furnace roll is mostly used for the vertical annealing furnace of continuous annealing and galvanizing lines. Under the nitrogen hydrogen protective atmosphere, the temperature is 750 ° C - 950 ° C in the furnace, and the strip steel is uniformly and rapidly transported to complete the annealing process; The diameter is 600-1500mm, the roll body is centrifugally cast, the transition section is statically cast, and the shaft head is mostly forged.

The coating furnace roll is mainly used in the vertical annealing furnace of high-end automobile plate and household appliance plate continuous annealing and galvanizing line. Under the nitrogen hydrogen protection atmosphere, the temperature is 750 ° C - 950 ° C, and the strip steel is transported evenly and rapidly to complete the annealing process; The diameter is 600-1500mm, and the furnace roll substrate is the same as the above. The surface coating improves the surface hardness of the furnace roll. The surface of the furnace roll is more stable during use, greatly reducing the surface scratches, and improving the quality of the plate. Common coatings: LC1C, WC, LCO56, LCO117, etc.

More Products